As photovoltaic (PV) solar energy continues to expand across remote locations such as highways and solar power stations, sandstorms and other climatic factors can significantly impact the efficiency of solar panels. Ensuring panel cleanliness has become a critical factor in maintaining optimal power generation performance.

Cleaning as a Core Component of PV Station Maintenance

In the routine operation and maintenance (O&M) of PV power stations, in addition to equipment inspection and performance monitoring, removing dust and contaminants from panel surfaces is an essential task.

Research shows that dust accumulation can reduce light transmission on PV modules, directly lowering power output. If left uncleaned, the buildup may lead to the “hotspot effect,” increasing module temperatures and potentially causing permanent damage.

To maintain stable energy output and maximize power generation efficiency, regular cleaning has become a fundamental part of O&M. Traditional manual cleaning methods are increasingly being replaced by intelligent, automated cleaning robots.

What Are the Advantages of Photovoltaic Cleaning Robots Over Manual Labor?

· Cost Efficiency: Automated cleaning reduces dependence on manual labor, significantly lowering operating costs while improving efficiency.

· Superior Cleaning Quality: Multiple adjustable cleaning modes provide consistent, traceable, and controllable results.

· Enhanced Safety: Replacing human workers in high-altitude or high-temperature environments reduces the risk of falls, burns, and electric shocks.

· Operational Transparency: Visualized and digitalized data management enhances operational decision-making capabilities.

· Water Conservation & Environmental Protection: Dry or low-water cleaning modes reduce water consumption and environmental impact.

Currently, the mainstream PV cleaning robots are primarily categorized into dry-contact and water-assisted types.

What Tasks Do Cutting-Edge PV Cleaning Robots Perform?

Through remote control or autonomous systems, PV cleaning robots perform dry or water-assisted cleaning across panel surfaces. They support multiple cleaning modes, intelligent path planning, and automatic navigation, making them adaptable to a wide range of PV array configurations, including variations in angle, size, and terrain.

Trinabot's R&D Approach to PV Cleaning Robots

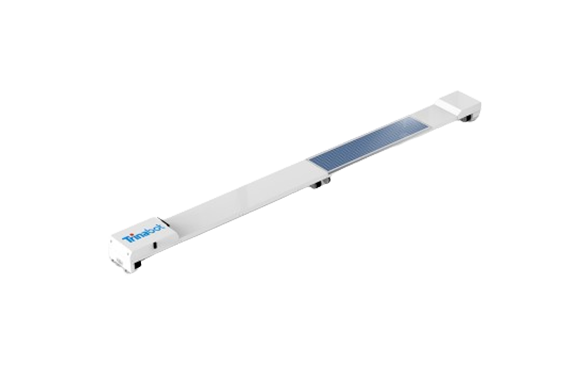

★ Trinabot Dry-Rail Mounted Cleaning Robots

These robots are installed on fixed tracks above the PV modules. The drive mechanism operates along the support rail to traverse and clean the panel surfaces using dry-contact cleaning components.

Trinabot's dry-rail robot is designed based on an innovative PV rail cleaning system. Given the complexity of field topographies, Trinabot tailors installation solutions to meet diverse project demands. Powered by solar-charged or battery systems and controlled via wireless networks, the robot supports remote operation, data tracking, and fault alerts—dramatically reducing manual intervention and enhancing management efficiency.

Key Advantages of Trinabot's Dry-Rail Robots:

· Compact and Easy to Deploy: Small, modular design allows for rapid deployment without dedicated tracks.

· Smart Control: Real-time monitoring, automated charging, path planning, and remote diagnostics.

· High Safety and Reliability: Rigorously tested structural integrity with long service life; powered by lithium or modular PACK batteries.

· Outstanding Environmental Protection: Fully sealed design meets IP65 standards, resistant to temperature extremes from -30°C to +60°C, strong winds, dust, snow, and ice.

★ Trinabot Crawler-Type Cleaning Robots

Equipped with self-driving capabilities, crawler robots do not require fixed rails and can travel between PV modules across different sections of a solar farm. They are ideal for large-scale ground-based power stations and offer flexible remote or autonomous operation.

Trinabot's crawler robot is engineered for large, complex terrains. Through intelligent mobility systems and modular cleaning components, it provides a customized solution for varying project requirements. With smart routing, autonomous turning, environmental sensing, and multi-layer obstacle avoidance, the robot achieves efficient, safe cleaning even in challenging environments.

Key Advantages of Trinabot's Crawler Robots:

· Quick Setup: Compact and modular for fast deployment.

· Efficient Cleaning Performance: Specialized cleaning tools effectively remove dust without damaging the PV surface. Water-assisted mode improves cleaning efficacy when needed.

· Non-Residual Cleaning Design: Advanced materials ensure no secondary dust or damage to panel surfaces.

· Intelligent Autonomy: Integrated positioning systems, route optimization, and data feedback enable full smart operation and remote control.

As Trinabot continues to deepen its expertise in PV cleaning technologies, our robotic solutions are not only improving efficiency but also accelerating time-to-market and enhancing smart manufacturing systems.

Looking ahead, Trinabot remains committed to innovation and R&D. By aligning with industry demands and leveraging upstream-downstream synergies, we aim to further optimize our robotic performance, expand cleaning applications, and push the boundaries of intelligent cleaning. We are dedicated to delivering high-efficiency, high-safety, low-carbon PV cleaning solutions that empower the renewable energy sector toward greater sustainability.

Empower Your Solar Investments—Partner with Trinabot for Smarter, Safer, and Cleaner Energy Solutions. Contact us today to learn more about how our PV cleaning robots can optimize your operations.